How to innovate in a well estabilished field with a high level of automation.

In the large-scale retail field there are a lot of different solutions for pallettizer and depallettizer systems and the technology is well known.

The question here is then: how can we innovate in such a well estabilished field, with a high level of automation?

The answers can span in a vaste number of aspects related to the technologies used in this field, like new grippers, collaborative robots, smart solenoids, … but why not taking into consideration also a review of the way in which the automated system, and their PLCs, are programmed?

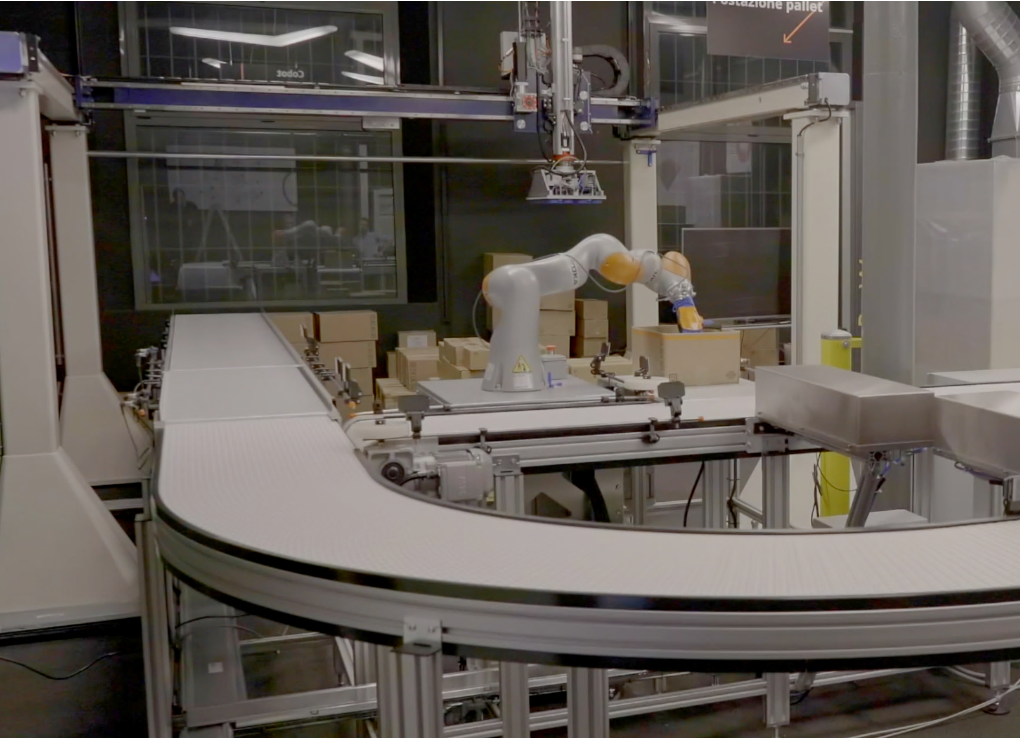

The activity we carried out in this project, partially financed by the European Research Council with the DAEDALUS project, devoted to the design of a small scale demo-plant to depallettize items from standard pallets and carry the packages to the proper output bay. This plant integrates technologies from multiple brands and it designed and programmed based on the IEC61499, a development paradigm for distributed automation of multi layer complex systems.

In this project we:

- Carried out the selection of the technologies to be integrated

- Designed the plant from both mechanical and electrical point of wiev

- Designed a new pneumatic grippers

- Programmed the application for the whole plant, distributed on 9 PLCs (standard IEC61499)

- Programmed the collaborative robot and smart valves

- Implemented a system to collect, monitor and visualize data from the plant for Industry 4.0

With this plant we demonstrated the possibility to leverage on the sinergy of innovative technologies as a key to build a small-scale industrial plant with high technological standards, based on advanced programming techniques for distributed automation.