Improve the knowledge about what is happening in your production environment

Synesis Digitalization Suite (SDS) is an hardware-software suite developed by Synesis over the years of experience in factory digitization projects in various industrial contexts. Today Synesis is therefore on the market with an effective and robust solution that allows you to continuously monitor the critical parameters of the production plants in order to store data and promptly detect anomalies and malfunctions. It is possible to monitor process or machine parameters, as well as energy consumption and performance of electrical, pneumatic and hydraulic systems.

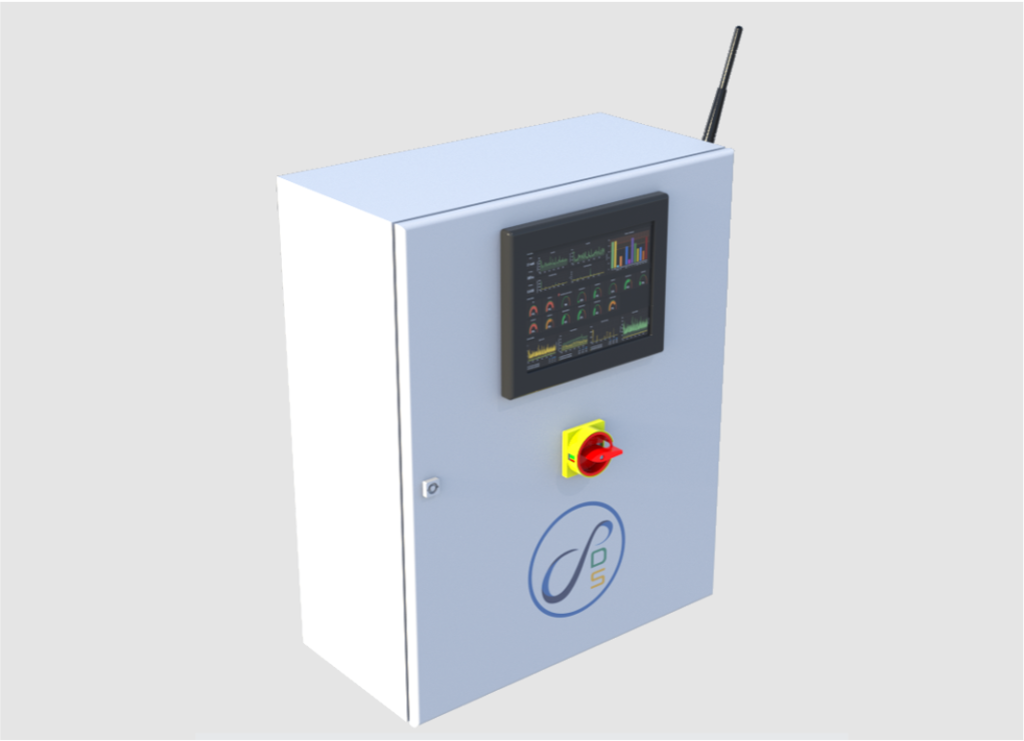

The system consists of an hardware data acquisition solution that can either be directly connected with sensors or with the machine controllers. The devices that compose the hardware solution have been carefully selected by Synesis which can leverage on decades of experience in projects of this nature.

After installing it, the system acquires the data and stores them. The Synesis Suite shows the acquired data on dashboards that can be customized according to the needs of the application and enriched with advanced analysis algorithms that allow you to identify anomalous behaviors, predict the trend of critical variables and make decisions based on real data.

In this way it is possible to improve the knowledge about what is really happening in the production plant, identifying anomalies, malfunctions and inefficiencies on which to fix in order to increase the overall performance of the factory.