Digitization of a press for hot molding of brass valves at Eurotermo

The digitalization of Eurotermo’s press was conceived to identify the critical parameters for the creation of cracks during the hot molding process of brass. In order to achieve this objective, a deep analysis of the molding process and the acquisition of metallurgy principles, which Eurotermo technicians were able to transfer to us, were necessary.

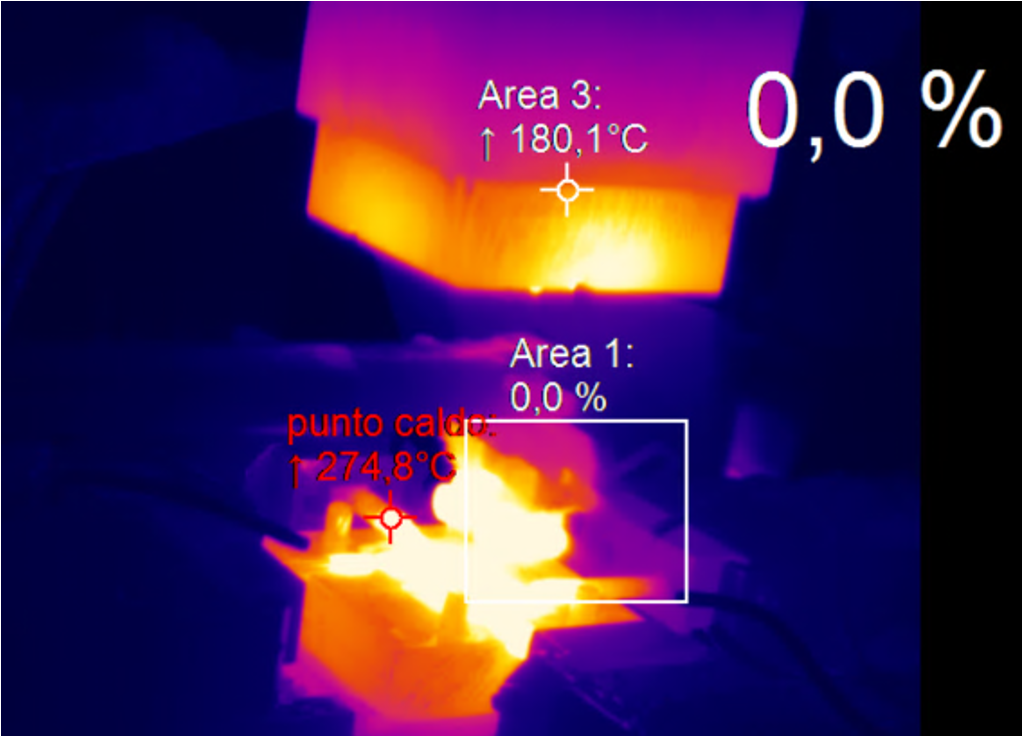

We have therefore identified the parameters to be monitored in order to provide the molding department with a window of parameters that guaranteed a correct printing process. The measurement of these parameters was carried out through the identification and implementation of latest generation sensor solutions: thermal imaging cameras for temperature control in the printing area, smart cameras for the correct positioning of the billet in the mold, pressure sensors and load cells for stress testing, special coatings for molds, 3D scanning tools for checking wear and tear on molds.

The data were then collected and processed by a software and hardware system provided by Synesis. The analysis algorithms, designed by Synesis engineers, allowed to define an acceptability grid for the processing of the pieces, which allowed to exclude the formation of dangerous cracks.

The demonstrated spirit of innovation makes Eurotermo a pioneer in the sector for the use of innovative data analysis technologies, according to the paradigms of industry 4.0.